The fashion industry is currently the 2nd MOST POLLUTING INDUSTRY in the WORLD. One of the main reasons is that the DEMAND for COTTON in this industry is very HIGH. And growing cotton requires a HUGE amount of PESTICIDES and WATER. This is why I want to show you how to produce a sustainable hemp thread for the textile industry!

Indeed, hemp is a MORE SUSTAINABLE ALTERNATIVE. Hemp, with FLAX and RAMIE, were more common in textiles back in time. Cotton recently became popular because textiles made of it are softer and easy to dye.

A lot of people think cotton became this much omnipresent because there have been a lot of lobbying about it. It is time to put an end to this!

In this article I will show you how to produce a sustainable hemp thread!

But why HEMP?

Hemp is a very interesting alternative to cotton. A hemp field will produce, for a same area, more fibers compared to a cotton field. Besides, hemp needs MUCH LESS WATER. To produce 1 kg of fibers the cotton needs 20.000 liters, whereas the hemp only needs 300 to 500 liters!

But that is not all! Hemp has exceptional ANTI-BACTERIAL and ANTI-FUNGAL natural properties. This plant is naturally stronger than others! It needs MUCH LESS PESTICIDES and HERBICIDES. Less pesticides means LESS ALLERGY and IRRITATION for the final customers. Pretty cool right? Note that these same natural strengths ease the job of the farmers to produce an ORGANIC HEMP.

Besides, hemp fibers are STRONG. For thousands of years people used them to make ropes and sails!

Many countries in the world forbade, or still forbid, the growing and the harvesting of hemp. This is because, with this same plant, one can also produce marijuana. But the growing techniques in this case are very different. But more and more countries around the world are legalizing marijuana, and this is a good thing for hemp.

It is a GOOD OPPORTUNITY. There is enough room for you to create your hemp business and serve a greater goal!

In this article, I will give you enough indications to start producing a sustainable HEMP THREAD on your own. After that you can sell it to textile companies so they can make MORE SUSTAINABLE CLOTHES.

I will assume you are already the happy owner of a hemp field like this one:

WHAT we WANT is to transform these plants above into THIS:

How to perform this TRANSFORMATION and with WHAT?

Next are the main steps required to produce a sustainable hemp thread. The first step is, of course, HARVESTING the hemp plants.

Retting the plants

The second step is the RETTING, the goal here is to prepare the hemp fibers to be ready for extraction.

Traditionally, RETTING is done by letting the harvested plants rotting few weeks. Soaking the plants in water help fasten this stage. But retting can be even faster with enzymes! The pectinase enzyme is told by many to be a very good ecological enzyme for retting (see here and here).

To start, you can buy PECTINASE enzymes on Alibaba for about 5 dollars per kg (prices may have changed).

Decortication to get the fibers

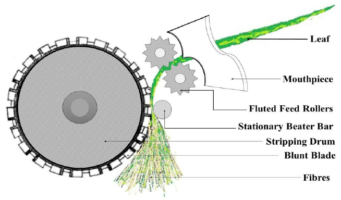

The third step is the DECORTICATION. Here, the fibers are mechanically removed from the rest of the plant.

Extracting the fibers from the plant (website).

A good RETTING will ease the DECORTICATION. This can be done by hands, like before. However, this is a very slow process. A decorticor machine will increase your productivity. But be sure to choose one not damaging the fibers! Modern decorticator machines can do the job pretty well. Some could even remove the fibers without a previous RETTING step!

You can buy a first cheap small decorticor machine on Alibaba for 6500 dollars (the prices may have changed).

Make sure to tick the “verified supplier” and “trader assurance” boxes when looking for a supplier on Alibaba.

A low investment hemp decorticor machine (here)

Scutching the fibers

We may also need to remove impurities from the raw material, this step is called the SCUTCHING.

A scutching machine on Alibaba for 5000 dollars .

Textiles made with hemp threads can be a little bit harsh to wear. Some people think it is one of the reasons why cotton is more popular. The reason why hemp fibers are a little bit harsh is because of the presence of LIGNIN. Enzymes can actually resolves this problem!

Actually LIGNIN and PECTIN can be removed in the same time during RETTING with a same enzyme.

Or you can perform an extra lignin removal after the SCUTCHING. This helps make your fibers even SMOOTHER, and textile companies will like it!

Carding the fibers

Directly, after the SCUTCHING, or an extra step of lignin removal, this is the CARDING of the fibers!

NO! I do not recommend you to use such a carding machine in your factory! You will spend too much time CARDING your fibers! Instead, you can buy a bigger one on Alibaba for 4000 dollars (the prices may have changed since the posting).

But what is the goal of carding by the way ? The goal of the CARDING is to disentangle and intermix the fibers and get a continuous web. Once done, it is ready for the SPINNING!

Spinning the fibers

And to finish, you guessed it, the SPINNING! Here the fibers are spinned into thread: our final product!

Again, there are cheap spinning machine on Alibaba. You can buy one for 6000 dollars (the prices may have changed).

And VOILA! You know the main steps to produce a sustainable HEMP THREAD so you can SELL IT to TEXTILE COMPANIES! More HEMP thread in the market means LESS USAGE of COTTON in the textile industry!

In this article I gave you a glimpse of the main steps you need to produce sustainable HEMP THREAD. As you can see, hemp textiles are a very good SUSTAINABLE ALTERNATIVE for the textile industry. The HABITS of this industry can be CHANGED by us. Changing industries’ habits through SOCIAL BUSINESS will contribute to CHANGE the WORLD efficiently.

There will be other articles on SustainableProfit.net about how to make the textile industry more sustainable for our planet. Actually, there are plenty of OTHER intersting FIBERS based on LINEN, RAMIE or even ALGAE! Let’s talk about it another time.

I would be happy to read your suggestions in the comments to make this article more useful for you! And if you notice a dead link or an outdated information, please let me know!

Bye!

We are starting a Hemp produce company in India…would like to have a conversation with you….regarding the amount and quantity that each machine can produce in one batch….

Impressive to see such a difference between different textiles. It’s a good idea to use more hemp in the textile industry instead of other materials which are less friendly to the environnement!!